oil extraction machine design pdf

Design Development of Oil Extractor. The shaft is mounted on bearings.

Groundnut Oil Expeller Assembly Diagram Fig 2 Isometric View Of The Download Scientific Diagram

The chemical extraction method is technically more effective and efficient for oil extraction.

. This machine is easy to maintain and economic for commercial uses. There is a universal demand for vegetable oil due to its increasing domestic and industrial uses. This work is intended to help solve some of the problems hindering a successful design and fabrication of oil extraction machine from nuts.

A small-scale JCS oil extraction machine was therefore designed developed and evaluated for performance. Despite its low cost the efficiency. 25 Methods of Extracting Essential Oil.

All the loads that are developed are applied on the shaft. To design develop and test expeller that is affordable to small scale oil millers. Separate between oil and non-oily solid NOS.

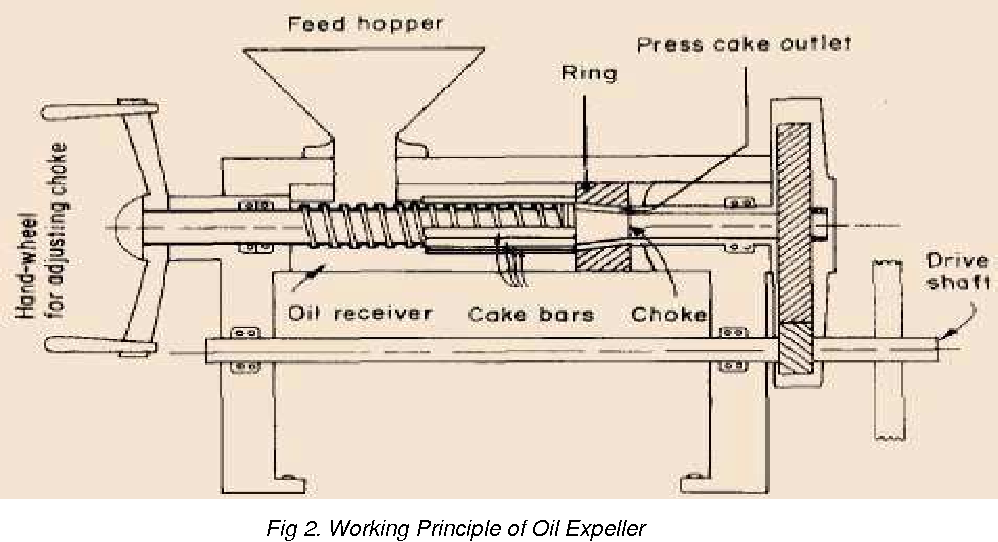

The expeller can be used for small scale groundnut oil extraction in the rural and urban communities. Design Analysis The design was carried out based on methodology given in machine design textbook 11 and literatures 12-14. The design of the oil expeller needs to be suitable for small-medium businesses where the total cost of setting up and running the machine is low.

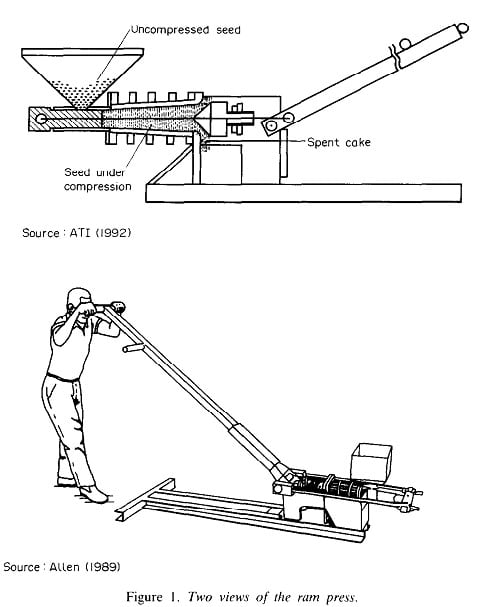

The Human Powered oil seed presser can be used to extract oil from seeds for a small scale quantity. Nonvolatile residueThis comprises 110 of the oil containing hydrocarbons fatty acids. The effecti veness of the screw press is very.

Essential oil constituting of 9095 of the oil in weight containing the monoterpene and sesquiterpene hydrocarbons as well as their oxygenated derivatives along with aliphatic aldehydes alcohols and esters. The design of the press is such that it can achieve operating pressures in excess of those obtained in most manually. The f144 Tanko Bako et al.

A decorticating machine. A Low Cost Oil Extraction Machine for Extraction of Oil from Gears Siddhesh Nanaware Prasanna Gondhale BE. In this study seed oil extraction methods have been investigated and various alternatives for the extraction machine have been considered.

Many methods of oil extraction exist but in general these are based on one of four principles. The design analysis was carried out to evaluate necessary design parameters for proper development of the machine. Oil is extracted from several seeds nuts and fruits Table 1 provides some common.

Modern Methods of Groundnut Crushing and Oil Extraction Saeed 1991 with the exit from the windless press and water mills the first mechanical screw press. This machine is designed in such a way that all the three processes. Indexed Terms- ASME shaft design Screw Mechanical Oil extraction expeller Stress analysis Efficiency I.

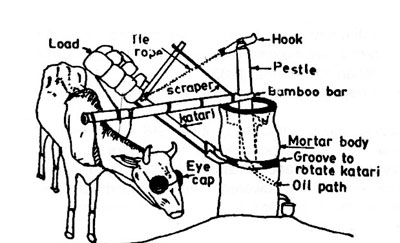

There is a universal demand for vegetable oil due to its increasing domestic and industrial uses. Oil extraction Practical Action 2 Dehusking is important to give high yields of oil and reduce the bulk of material to be processed but in groundnut oil extraction about 10 by weight of husk should be added back to the nuts to allow oil to escape more freely from the press. It has been used in solid -liquid separatio n of extraction pal m oil machine purposely is to.

Oil extraction machine specific to canola seed. The machine was designed to run with 3 hp single phase electric motor at a speed of 540 revmin based on impact compressing and shearing force on the roasted groundnut. There are five mechanisms which facilitate proper functioning of sieving and milling machine.

Production of its oil. 15 26 Extraction of Essential Oil by using Steam Distillation method 18 27 Application of oil Extracted from Eucalyptus 21 Chapter 3 EXPERIMENTAL WORK 24-31 31 Experimental Set-up 25 32 Experimental Procedure 27 33 Experimental Observations 28 34 Analysis of Essential Oil Study 29. The physical process involves the use of manual squeezing of ground nut sample by hand.

One is physical process and another is chemical process. For domestic purposes human mechanical power can be used to extract oil from. Decortication is important to give high yields of oil and.

Roasting of groundnut Separation of groundnut shells from the groundnut seed and the oil extraction is done in a single unit without any human interference. The rate of vegetable oil consumption is increasing compared to both animal fats due to its health implication Akinoso 2006. Many methods of oil extraction exist but in general these are based on one of four principles.

Coconut is dehusked and split by. Easier oil extraction there are Various Method of Extraction of Oil such as Distillation Expression Effleurage Maceration Extraction of Oil By Oil Seed Presser. INTRODUCTION Oil expeller is a device which can produce pressure by rotating feed to expeller screw manually or automatically.

For continuous operation oil extraction with a screw press. The design of this Jatropha oil expelling machine will enhance the production of biodiesel from Jatropha seeds. To develop a machine that can extract oil from groundnut within a minimum time frame.

Screw press method for oil extraction is a mechanical method for extracting oil from raw materials. There are two main types of processes for extraction of oil from oil seeds. It has been used in solid -liquid separatio n of extraction pal m oil machine purposely is to.

The rate of vegetable oil consumption is increasing compared to both animal fats due to its health implication Akinoso 2006. Help in design development REFERENCES 1 Dennis Gimpert Gear Fundamentals The gear Hobbing process pg- 40. MACHINE DESIGN Design calculation The low-cost groundnut oil extracting machine was developed with locally available materials.

In the analysis the bearings are substituted by cylindrical supports. Machine that produces the part during the design of the machine and the drafting software was used to draw the orthogonal views Isometric views exploded drawings fig 4 shows the detailed drawing of the machine modeling and simulation was done before the commencement of the fabrication processes. Conceptual Design of a Fish Oil Extracting Machine pressure reaches a maximum of 12 MPa at the pressing region.

The study was conducted using 3 3. Manually-operated groundnut decorticating machine. Bowl feeder crushing rollers conveyor tray vibrating tray hopper and.

The designs of the crushing system and pre-heating systems before pressing will enable the machine operate at efficiency greater than 90.

Camartec Oil Press Machine Engineering For Change

Semi Sectional View Of The Screw Press Oil Expeller Download Scientific Diagram

Custom Made Pressing Machine Soybean Oils Machine Sunflower Seeds

Structural Drawing And Brief Introduction Of Screw Oil Press Structural Drawing Mechanical Design Machine Design

Pdf Parameters Influencing The Screw Pressing Process Of Oilseed Materials

Cold Press Hydraulic Oil Press Machine For Seeds Oil Extraction

Groundnut Oil Expeller Assembly Diagram Fig 2 Isometric View Of The Download Scientific Diagram

Pdf Design And Fabrication Of Motorized Hydraulically Operated Palm Oil Press

A Review On Design And Analysis Of Oil Expeller Spares Semantic Scholar

Mechanical Extraction Processing Technology For Biodiesel Farm Energy

Design And Stress Analysis Of Screw Shaft For Peanut Oil Screw Press Expeller Semantic Scholar

Build Your Own Oil Press Yields Oil And Dry Nut Meal Oh Wind Powered Too Low Tech Forum At Permies